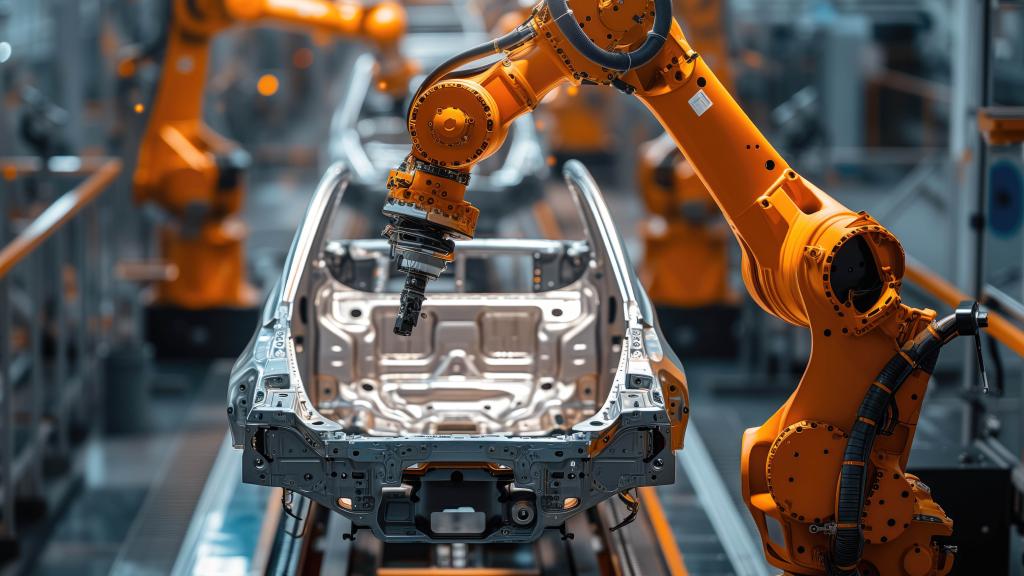

In a groundbreaking move poised to change the automotive industry, a Pennsylvanian company has been running simulations to test the viability of recycled plastics being transformed into automotive parts.

Here are the key points:

- The company is leveraging stimulation technology to revolutionise the materials used by original equipment manufacturers (OEMs)

- Through simulations, materials like plastic can be tested to showcase their efficacy and reduce costs for OEMs

- If successful, the invention of recycled automotive parts could reduce the emissions produced during the manufacturing process.

Not only could recycled car parts reduce emissions during the manufacturing process, but they could also reduce emissions from creating replacement parts. This could lower overall emissions produced by the automotive industry drastically, changing the perspective and potentially making this once ticking-time-bomb industry sustainable for longer.

While the potential benefits of OEMs using recycled materials to create automotive parts are numerous, there are some challenges. The quality and collection methods of the recycled materials may impact their efficacy for use as automotive parts, and market perceptions about quality could cause roadblocks if this technology is used on a large scale. These issues could prevent the use of recycled plastics being used for automotive parts altogether if left unsolved.

Regardless of the outcome, these tests give merit to the concept of stimulation, highlighting how important it can be as well as how it can reduce the costs of potential innovations. It also shows a growing interest in sustainability as more tech companies look for new solutions to reduce emissions. A world where the vast majority of cars are made out of recycled plastics may be right around the corner.